If you have been following the news, you are likely aware of the recent water contamination crisis in North Carolina and several other states. Many communities have been affected by high levels of GenX and other PFAS chemicals in their drinking water. One option that has been suggested is using carbon filters to remove these contaminants from drinking water. But does this really work?

Activated carbon is effective for removing many PFAS compounds, including GenX chemicals. PFAS is a group of more than 4,000 compounds, and the effectiveness of carbon filtration varies depending on the specific compound. In general, carbon filters are more effective for treating larger molecules, such as GenX. For smaller PFAS molecules, reverse osmosis or ion exchange are better options. A properly designed and well-maintained carbon filter system is essential to reduce concentrations of these contaminants to drinking water standards.

If you have PFAS in your water, or just want to learn more about carbon filters and how well they treat this group of contaminants, continue reading.

What is PFAS and GenX

PFAS is an acronym for “per- and polyfluoroalkyl substances.” This is a group of more than 4,000 man-made chemicals. All PFAS compounds contain fluorine atoms that are bonded to carbon chains. These substances have been used in many industries since the 1950s, and are ingredients used to make things like stain-resistant coatings, nonstick cookware, water-repellent clothing, and food packaging.

GenX is one type of PFAS that has been in the news recently because it has been found in high levels in the drinking water near Wilmington, North Carolina. Both PFAS and GenX have been described as “emerging contaminants”. This term applies to unregulated compounds that have the potential to enter the environment and cause adverse ecological and/or human health effects.

What are forever chemicals

PFAS compounds are called “forever chemicals” because they don’t break down in the environment or in our bodies. They persist in the environment for decades without degrading or dissipating. These chemicals can build up in people’s bodies over time and have been linked to a variety of health problems, including cancer, thyroid disease, and reproductive issues.

What is GenX

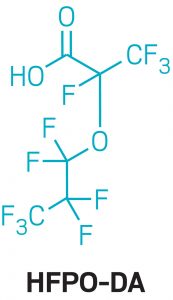

GenX is a man-made chemical that Chemours developed to replace highly toxic compounds such as PFOS and PFOA. It is the ammonium salt of hexafluoropropylene oxide dimer acid (HFPO-DA).

This compound is one in a family of chemicals known as PFECAs. Although GenX was initially thought to be safe, recent evidence suggests that this compound is toxic to human health.

How do PFAS and GenX get in my drinking water

Groundwater and surface water are used as drinking water sources throughout the country. These drinking water supplies are at risk of contamination from PFAS and GenX because of the widespread use of these chemicals and their persistence in the environment.

Contamination of drinking water from PFAS is typically found in close proximity to industrial facilities where these chemicals were produced or used to make other substances. Other sources of contamination include airfields and firefighting training facilities where PFAS-containing foams were used.

Health concerns with PFAS and GenX

The health risks associated with PFAS vary from compound to compound – each has its own properties and hazards. Recent studies have linked PFAS to:

- kidney and testicular cancer

- liver function abnormalities

- immunotoxicity

- endocrine disruption

- thyroid disease

- high cholesterol

- ulcerative colitis

- pregnancy-induced hypertension

New evidence indicates that GenX also causes health problems. The National Institute for Public Health and the Environment of the Netherlands concluded that GenX chemicals are a suspected human carcinogen.

Drinking water standard for PFAS and GenX

The Safe Drinking Water Act is a law that requires the Environmental Protection Agency (EPA) to establish drinking water quality standards for public water systems. Approximately 90% of Americans get their water from these public water systems. The remaining 10% of Americans have private drinking water wells that aren’t regulated by the EPA.

The EPA is required to establish maximum contaminant levels (MCLs) for pollutants in public drinking water supplies. MCLs are the highest concentration of a contaminant allowed in drinking water.

Currently, there is no MCL for any PFAS compound.

The EPA has established a health advisory level of 70 parts per trillion (ppt) for PFOA and PFOS (combined total). Health advisories are non-enforceable recommendations that are based on health effects associated with drinking water contamination.

Current EPA Health Advisories for PFAS compounds include:

- PFOA = 0.004 parts per trillion (ppt)

- PFOS = 0.02 ppt

- GenX chemicals = 10 ppt

- PFBS = 2,000 ppt

Activated Carbon

Activated carbon adsorption is an effective and reliable water treatment process. It is considered a best available control technology by the USEPA and is a benchmark for other water treatment methods. Carbon filters are widely used in residential and commercial water treatment systems to remove a variety of contaminants including taste and odor, chlorination byproducts, VOCs, and THMs.

Read my comprehensive Carbon Design Guide for a detailed explanation of this treatment technology.

How carbon adsorption works

Adsorption is a physical process where contaminants are removed from water by binding to the surface of the carbon media. Adsorption is different than absorption. Adsorption, which is how carbon filters work, is a physical attraction that attracts a contaminant to the surface of the carbon.

Absorption is a bulk process where the substance is taken into (absorbed) the media like a sponge. Adsorption onto activated carbon works because most organic molecules have a natural affinity for carbon. This means they will stick to the surface of the carbon. To increase the surface area available for adsorption, thousands of tiny pores are created by “activating” the carbon.

Carbon filter components

Carbon filters for residential applications are very simple. They include either a vessel filled with activated carbon (for whole-house systems) or a cartridge that contains carbon (point-of-use filters).

Granular activated carbon, also known as GAC, is the most commonly used type of carbon. GAC looks like the gravel in an aquarium.

Some carbon filters include a particle pre-filter to remove sediment and suspended particles. This protects the carbon from fouling and extends the life of the media.

Many carbon filters, especially whole-house systems, include a bypass valve to allow the flow of water when the vessel is being serviced. Pressure gauges are often installed on the inlet and discharge side of the filter to allow you to monitor the amount of fouling that has occ

Types of granular activated carbon

Carbon is formed by converting organic materials like wood and coal into charcoal. The charcoal is then activating by exposing it to high temperature steam.

1 – Coal-based carbon

Most of the activated carbon used in water treatment is made from coal. The two main types use in carbon are bituminous coals and lignite coal. Coal-based carbon is very hard with pore sizes that make it ideal for removing many of the contaminants found in drinking water.

2 – Coconut shell carbon

Coconut shall carbon is highly prized for its ability to purify air and to remove difficult contaminants like PFAS and lead. This carbon is made from coconut husks. Coconut shell carbon is more expensive than coal-based carbon, but it lasts longer and is more effective at removing certain types of contaminants.

3 – Catalytic carbon

Catalytic carbon is activated carbon that has been modified through the addition of iron-hydroxide or through an enhanced activation process. It has several advantages over conventional carbon including a higher affinity for chlorine and chloramines.

How Well Does Carbon Filtration Remove PFAS and GenX Compounds

Activated carbon can be used to remove many PFAS compounds from drinking water. Carbon filtration works very well for GenX and other large molecules. Some PFAS compounds, especially the shorter molecules, do not adsorb onto carbon.

How much PFAS and GenX can carbon remove

The performance of activated carbon with PFAS and GenX varies with each molecule. This issue becomes challenging because there are more than 4,000 PFAS compounds.

We conducted an exhaustive survey of university and government studies looking at how well carbon removes PFAS compounds. We found more than 230 studies!

Each report we reviewed included testing of specific compounds. Some of the research only evaluated 1 or 2 compounds. Others reviewed dozens.

We extracted the results for each PFAS compound and provided a qualitative assessment to make a useful comparison. Our ranking for how well carbon removes a PFAS compound is:

- Excellent – Carbon removes 95 to >99% of PFAS

- Good – Carbon removes 85 – 95% of PFAS

- Fair – Carbon removes 75 – 85% of PFAS

- Poor – Carbon removes less than 75% of PFAS

- Unknown – Carbon removal not provided numerically

The following table provides an assessment of how well carbon removes specific PFAS compounds.

| Acronym | PFAS Name | Removal with Carbon |

| PFBA | Perfluorobutanoic acid | Good |

| PFBS | Perfluorobutane sulfonic acid | Good |

| PFDA | Perfluorodecanoic acid | Excellent |

| PFDoDA | Perfluorododecanoic acid | Excellent |

| PFDS | Perfluorodecane sulfonic acid | Excellent |

| PFHpA | Perfluoroheptanoic acid | Excellent |

| PFHpS | Perfluoroheptane sulfonic acid | Excellent |

| PFHxA | Perfluorohexanoic acid | Excellent |

| PFHxS | Perfluorohexane sulfonic acid | Excellent |

| PFNA | Perfluorononanoic acid | Excellent |

| PFNS | Perfluorononane sulfonic acid | Unknown |

| PFOA | Perfluorooctanoic acid | Excellent |

| PFOS | Perfluorooctane sulfonic acid | Excellent |

| PFPeA | Perfluoropentanoic acid | Excellent |

| PFPeS | Perfluoropentane sulfonic acid | Unknown |

| PFTeDA | Perfluorotetradecanoic acid | Excellent |

| PFTrDA | Perfluorotridecanoic acid | Excellent |

| PFUnA | Perfluoroundecanoic acid | Excellent |

| 10:2 FTSA | 10:2 Fluorotelomer sulfonic acid | Unknown |

| 4:2 FTSA | 4:2 Fluorotelomer sulfonic acid | Unknown |

| 5:3 FTCA | 5:3 Fluorotelomer carboxylic acid | Unknown |

| 6:2 FTCA | 6:2 Fluorotelomer carboxylic acid | Fair |

| 6:2 FTSA | 6:2 Fluorotelomer sulfonic acid | Excellent |

| 8:2 FTSA | 8:2 Fluorotelomer sulfonic acid | Excellent |

| EtFOSA | N-Ethyl perfluorooctane sulfonamide | Excellent |

| EtFOSE | N-Ethyl perfluorooctane sulfonamidoethanol | Excellent |

| FOSA/PFOSA | Perfluorooctane sulfonamide | Excellent |

| FOSE | Perfluorooctane Sulfonamidoethanol | Unknown |

| MeFOSA | N-Methyl perfluorooctane sulfonamide | Unknown |

| MeFOSE | N-Methyl perfluorooctane sulfonamidoethanol | Unknown |

| EtFOSAA | N-Ethyl perfluorooctane sulfonamido acetic acid | Excellent |

| FOSAA | Perfluorooctane sulfonamido acetic acid | Unknown |

| MeFOSAA | N-Methyl perfluorooctane sulfonamido acetic acid | Excellent |

| 10:2 FTOH | 10:2 Fluorotelomer alcohol | Excellent |

| 4:2 FTOH | 4:2 Fluorotelomer alcohol | Fair |

| 6:2 FTOH | 6:2 Fluorotelomer alcohol | Excellent |

| 8:2 FTOH | 8:2 Fluorotelomer alcohol | Excellent |

| 11Cl-PF3OUdS | 11-chloroeicosafluoro-3-oxaundecane-1-sulfonic acid | Excellent |

| 9Cl-PF3ONS | 9-chlorohexadecafluoro-3-oxanone-1-sulfonic acid | Excellent |

| HFPO-Dab | Hexafluoropropylene oxide dimer acid | Good |

| NFDHA | Perfluoro-3,6-dioxaheptanoic acid | Unknown |

| PFEESA | Perfluoro(2-ethoxyethane)sulfonic acid | Unknown |

| PFMBA | Perfluoro-4-methoxybutanoic acid | Unknown |

| PFMPA | Perfluoro-3-methoxypropanoic acid | Unknown |

| ADONA | 4,8-dioxa-3H-perfluorononanoic acid | Good |

| FTSAs | Fluorotelomer sulfonic acids | Unknown |

Carbon filter requirements for good PFAS removal

In general, carbon filtration is an effective way to remove PFAS from drinking water. As noted in the table above, many of these forever compounds can be treated very effectively with activated carbon.

One significant challenge, however, is the extremely low drinking water standard for PFAS. The EPA recommends 70 parts per trillion. This is a very low level!

To treat water to ppt levels, requires a very high level of treatment. It is important to have a properly designed and well-maintained system.

A PFAS carbon treatment system must have the following design components to work properly:

- Adequate amount of carbon: A whole-house carbon filter must have at least 100 pounds of activated carbon. Any less, and PFAS can breakthrough and expose you to these dangerous chemicals.

- Two carbon vessels plumbed in series: Achieving the extremely low drinking water standard (70 ppt) is very difficult. To get to the parts per trillion level, you need two filters working together. The first unit does the heavy lifting and removes most of the PFAS. The second unit is for polishing and removes the small amount that gets through the first filter.

- Pre-treatment filter to remove suspended solids: Fouling of the carbon bed can cause channeling and block pores inside the carbon. A high-quality sediment filter is required to remove all solids and turbidity.

- Post-treatment filter to remove carbon fines: A particle filter is needed to remove carbon fines that might contain adsorbed PFAS.

- Flow meter: A flow meter is needed to keep track of the volume of water treated. Carbon has a limited capacity to remove PFAS, and volume of treated water is a good way to estimate when it’s time to replace the media.

- Sample ports: You should sample your drinking water once per month to confirm that the carbon is adequately removing the PFAS. Collect a sample between the two carbon filters to know when the first unit is spent.

Challenges with PFAS and carbon

Carbon adsorption does not destroy PFAS, it merely removes it from the water by accumulating it on the carbon. If you simply dump the spent carbon in your backyard or in your garbage, the PFAS can be released into the environment again. Therefore, the spent carbon must be properly disposed of. Disposal can be expensive because there are limited options available – incineration and landfills.

Limitations of under-sink carbon filters

Many people use under-sink carbon filters to remove PFAS and GenX chemicals from their water. These filters have mixed results.

Some of the challenges with these smaller filters is that they typically don’t have a lot of carbon in them. This means that they can remove a small amount of PFAS but they quickly become spent. At this point, you have increasing amounts of these fluorinated contaminants in your water.

Another limitation of point-of-use carbon filters is that they provide limited contact time, which limits their ability to reduce the contaminants to ppt levels. You also need two filters in series. You can do this with under-sink filters – you just need to install two.

My advice is to use a whole-house carbon filter to remove PFAS from your drinking water. You can use an under-sink carbon filter as an insurance policy to remove any contaminants that pass through your main treatment.

NSF Certified Filters for PFAS Treatment

Given the health risks with forever chemicals, you need a carbon filter that can do the job. This means your filter has to remove all of the PFAS. But how can you tell if the filter you’re considering can meet the manufacturer’s claims?

This is where NSF comes in. NSF is a third-party testing agency that verifies all of the claims made by filter manufacturers.

They have a certification based on health effects – NSF/ANSI 53: Drinking Water Treatment Units – Health Effects. Loof for NSF / ANSI 53 certification on your carbon filter to be certain it can remove PFAS from your water.

For a product to be certified to remove PFOA and PFOS, the filter must reduce the concentration to below the EPA healthy advisory limit of 70 parts per trillion. NSF retests each certified product periodically and inspects the manufacturing facility every year. This rigorous oversight ensures the filter will continue to meet all requirements.

The following table lists every carbon filter that is certified by NSF to remove PFOA an PFOS from drinking water.

|

Brand |

Model Number |

Service Cycle (gallons) |

Filter Type |

|

A.O. Smith |

AO-US-200 |

500 |

Under-sink |

|

A.O. Smith |

AOW-2000 |

500 |

Under-sink |

|

A.O. Smith |

AOW-3000[2] |

365 |

Under-sink |

|

A.O. Smith |

AO-CWM |

320 |

Countertop |

|

A.O. Smith |

AO-US-RO-4000 |

365 |

Under-sink |

|

Amway |

eSpring Model 100185 |

1,320 |

Countertop |

|

Amway |

eSpring Model 100185 |

1,320 |

Countertop |

|

Amway |

eSpring Model 100185 |

1,320 |

Countertop |

|

Amway |

eSpring Model 100185 |

1,320 |

Countertop |

|

Amway |

eSpring Model 100185 |

1,320 |

Countertop |

|

Amway |

eSpring Model 100185 |

1,320 |

Countertop |

|

Amway |

eSpring Model 100185 |

1,320 |

Countertop |

|

Amway |

eSpring Model 100185 |

1,320 |

Countertop |

|

Amway |

eSpring Model 100185 |

1,320 |

Countertop |

|

Amway |

eSpring Model 100185 |

1,320 |

Countertop |

|

Amway |

eSpring Model 100185A |

1,320 |

Countertop |

|

Amway |

eSpring Model 100185B |

1,320 |

Countertop |

|

Amway |

eSpring Model 100185D |

1,320 |

Countertop |

|

Amway |

eSpring Model 100185HS |

1,320 |

Countertop |

|

Amway |

eSpring Model 100185MX |

1,320 |

Countertop |

|

Amway |

eSpring Model 100185NC |

1,320 |

Countertop |

|

Amway |

eSpring Model 100185P |

1,320 |

Countertop |

|

Amway |

eSpring Model 100185PH |

1,320 |

Countertop |

|

Amway |

eSpring Model 100185SK |

1,320 |

Countertop |

|

Amway |

eSpring Model 100185UA |

1,320 |

Countertop |

|

Amway |

eSpring Model 100185W |

1,320 |

Countertop |

|

Amway |

100186E |

1,320 |

Under-sink |

|

Amway |

100186J |

1,320 |

Under-sink |

|

Amway |

100186K |

1,320 |

Under-sink |

|

Amway |

100186M |

1,320 |

Under-sink |

|

Amway |

100186ME |

1,320 |

Under-sink |

|

Amway |

100186MX |

1,320 |

Under-sink |

|

Amway |

100186R |

1,320 |

Under-sink |

|

Amway |

100186RK |

1,320 |

Under-sink |

|

Amway |

100186T |

1,320 |

Under-sink |

|

Amway |

100186TH |

1,320 |

Under-sink |

|

Amway |

CVX5787 |

1,320 |

Under-sink |

|

Amway |

eSpring Model 100185 |

1,320 |

Under-sink |

|

Amway |

eSpring Model 100185 |

1,320 |

Under-sink |

|

Amway |

eSpring Model 100185 |

1,320 |

Under-sink |

|

Amway |

eSpring Model 100185 |

1,320 |

Under-sink |

|

Amway |

eSpring Model 100185 |

1,320 |

Under-sink |

|

Amway |

eSpring Model 100185 |

1,320 |

Under-sink |

|

Amway |

eSpring Model 100185 |

1,320 |

Under-sink |

|

Amway |

eSpring Model 100185 |

1,320 |

Under-sink |

|

Amway |

eSpring Model 100185 |

1,320 |

Under-sink |

|

Amway |

eSpring Model 100185A |

1,320 |

Under-sink |

|

Amway |

eSpring Model 100185B |

1,320 |

Under-sink |

|

Amway |

eSpring Model 100185D |

1,320 |

Under-sink |

|

Amway |

eSpring Model 100185GR |

1,320 |

Under-sink |

|

Amway |

eSpring Model 100185HS |

1,320 |

Under-sink |

|

Amway |

eSpring Model 100185MX |

1,320 |

Under-sink |

|

Amway |

eSpring Model 100185NC |

1,320 |

Under-sink |

|

Amway |

eSpring Model 100185P |

1,320 |

Under-sink |

|

Amway |

eSpring Model 100185R |

1,320 |

Under-sink |

|

Amway |

eSpring Model 100185SA |

1,320 |

Under-sink |

|

Amway |

eSpring Model 100185SK |

1,320 |

Under-sink |

|

Amway |

eSpring Model 100185UA |

1,320 |

Under-sink |

|

Amway |

eSpring Model 100185W |

1,320 |

Under-sink |

|

Amway |

100186E |

1,320 |

Under-sink |

|

Amway |

100186J |

1,320 |

Under-sink |

|

Amway |

100186K |

1,320 |

Under-sink |

|

Amway |

100186M |

1,320 |

Under-sink |

|

Amway |

100186ME |

1,320 |

Under-sink |

|

Amway |

100186MX |

1,320 |

Under-sink |

|

Amway |

100186R |

1,320 |

Under-sink |

|

Amway |

100186RK |

1,320 |

Under-sink |

|

Amway |

100186T |

1,320 |

Under-sink |

|

Amway |

100186TH |

1,320 |

Under-sink |

|

Amway |

CVX5787 |

1,320 |

Under-sink |

|

Amway |

eSpring Model 100185 |

1,320 |

Under-sink |

|

Amway |

eSpring Model 100185 |

1,320 |

Under-sink |

|

Amway |

eSpring Model 100185 |

1,320 |

Under-sink |

|

Amway |

eSpring Model 100185 |

1,320 |

Under-sink |

|

Amway |

eSpring Model 100185 |

1,320 |

Under-sink |

|

Amway |

eSpring Model 100185 |

1,320 |

Under-sink |

|

Amway |

eSpring Model 100185 |

1,320 |

Under-sink |

|

Amway |

eSpring Model 100185 |

1,320 |

Under-sink |

|

Amway |

eSpring Model 100185 |

1,320 |

Under-sink |

|

Amway |

eSpring Model 100185A |

1,320 |

Under-sink |

|

Amway |

eSpring Model 100185B |

1,320 |

Under-sink |

|

Amway |

eSpring Model 100185D |

1,320 |

Under-sink |

|

Amway |

eSpring Model 100185GR |

1,320 |

Under-sink |

|

Amway |

eSpring Model 100185HS |

1,320 |

Under-sink |

|

Amway |

eSpring Model 100185MX |

1,320 |

Under-sink |

|

Amway |

eSpring Model 100185NC |

1,320 |

Under-sink |

|

Amway |

eSpring Model 100185P |

1,320 |

Under-sink |

|

Amway |

eSpring Model 100185R |

1,320 |

Under-sink |

|

Amway |

eSpring Model 100185SA |

1,320 |

Under-sink |

|

Amway |

eSpring Model 100185SK |

1,320 |

Under-sink |

|

Amway |

eSpring Model 100185UA |

1,320 |

Under-sink |

|

Amway |

eSpring Model 100185W |

1,320 |

Under-sink |

|

Amway |

eSpring Model 100188CH |

1,320 |

Countertop |

|

Aquasana |

AQ-CWM-D-B |

320 |

Countertop |

|

Aquasana |

AQ-CWM-D-W |

320 |

Countertop |

|

Aquasana |

AQ-CWM-P-B |

320 |

Countertop |

|

Aquasana |

AQ-CWM-P-W |

320 |

Countertop |

|

Aquasana |

AQ-CWM-RB1 |

320 |

Countertop |

|

Aquasana |

AQ-CWM-RB1W |

320 |

Countertop |

|

Aquasana |

AQ-CWM-RB2 |

320 |

Countertop |

|

Aquasana |

AQ-PCBK-BT |

320 |

Countertop |

|

Aquasana |

AQ-PCBK-GC |

320 |

Countertop |

|

Aquasana |

AQ-PCW-BT |

320 |

Countertop |

|

Aquasana |

AQ-PCW-GC |

320 |

Countertop |

|

Aquasana |

AQ-PWFS-D-B |

320 |

Countertop |

|

Aquasana |

AQ-PWFS-D-W |

320 |

Countertop |

|

Aquasana |

AQ-PWFS-P-B |

320 |

Countertop |

|

Aquasana |

AQ-PWFS-P-W |

320 |

Countertop |

|

Aquasana |

AQ-PWFS-RB-2 |

320 |

Countertop |

|

Aquasana |

AQ-PWFS-RB1 |

320 |

Countertop |

|

Aquasana |

AQ-PWFS-RB1-W |

320 |

Countertop |

|

Aquasana |

AQ-PWFS-RB3 |

320 |

Countertop |

|

Aquasana |

AQ-5300+.NF |

800 |

Under-sink |

|

Aquasana |

AQ-5300+ |

800 |

Under-sink |

|

Aquasana |

AQ-5300A |

1,095 |

Under-sink |

|

Aquasana |

OptimH2O™ AQ-RO-3 |

365 |

Under-sink |

|

Aquasana |

AQ-4000 |

450 |

Countertop |

|

Aquasana |

AQ-4000B |

450 |

Countertop |

|

Aquasana |

AQ-4000B-Prem |

450 |

Countertop |

|

Aquasana |

AQ-4000P |

450 |

Countertop |

|

Aquasana |

AQ-4000P-STD |

450 |

Countertop |

|

Aquasana |

AQ-4000W |

450 |

Countertop |

|

Aquasana |

AQ-4000W-Prem |

450 |

Countertop |

|

Aquasana |

AQ-5200 |

500 |

Under-sink |

|

Aquasana |

AQ-5300 |

600 |

Under-sink |

|

Aquasana |

HF-2STAGE-BN |

450 |

Under-sink |

|

Aquasana |

HF-2STAGE-CN |

450 |

Under-sink |

|

Carbon Block Technology |

CB-AS |

600 |

Under-sink |

|

Culligan |

POE PFCs REDUCTION SYSTEM |

164,000 |

Point-of-Entry |

|

Hydroviv |

HYDROVIV-US-SRS-14cZIP |

360 |

Under-sink |

|

Hydroviv |

HYDROVIV-US-SRS-18pZIP |

450 |

Under-sink |

|

Hydroviv |

HYDROVIV-US-SRS-43pZIP |

450 |

Under-sink |

|

Hydroviv |

HYDROVIV-US-SRS-46cZIP |

360 |

Under-sink |

|

Hydroviv |

HYDROVIV-US-SRS-71xZIP |

600 |

Under-sink |

|

Hydroviv |

HYDROVIV-US-SRS-74pZIP |

450 |

Under-sink |

|

Hydroviv |

HYDROVIV-US-SRS-75cZIP |

360 |

Under-sink |

|

Kinetico |

KPMF Series |

5,700 |

Point-of-Entry |

|

Kinetico |

KPMF Series |

2,000 |

Point-of-Entry |

|

Kinetico |

PFAS POU |

2,000 |

Point-of-Entry |

|

LG |

ADQ747937 |

200 |

Refrigerator |

|

Multipure |

AQUALUXE |

500 |

Under-sink |

|

Multipure |

Aquaperform |

600 |

Under-sink |

|

Multipure |

CB-EXTRA |

340 |

Under-sink |

|

Samsung |

RWPaxy1bcde |

660 |

Under-sink |

|

Samsung |

RWP70010TWW |

660 |

Refrigerator |

|

Tupperware |

Nano Nature TPW-C1 |

1,325 |

Countertop |

|

Tupperware |

Nano Nature TPW-C2 |

1,325 |

Countertop |

|

Tupperware |

Nano Nature Water Filtration System |

1,325 |

Countertop |

|

Tupperware |

Nano Nature TPW2-C1 |

1,325 |

Countertop |

|

Watpure |

WTPAs |

600 |

Under-sink |

|

ZeroWater |

ZBD-040 2.5 Gal Glass Dispenser |

20 |

Pitcher |

|

ZeroWater |

ZD-010RP |

20 |

Pitcher |

|

ZeroWater |

ZD-012RP |

20 |

Pitcher |

|

ZeroWater |

ZD-018 |

20 |

Pitcher |

|

ZeroWater |

ZD-023-1 |

20 |

Pitcher |

|

ZeroWater |

ZD-030RP 30 Cup Ready-Pour Dispenser |

20 |

Pitcher |

|

ZeroWater |

ZD-20RPN 20-Cup |

20 |

Pitcher |

|

ZeroWater |

ZP-006 |

20 |

Pitcher |

|

ZeroWater |

ZP-007RP |

20 |

Pitcher |

|

ZeroWater |

ZP-010 |

20 |

Pitcher |

|

ZeroWater |

ZR-0810GN 8-Cup RedyPour Round Pitcher |

20 |

Pitcher |

|

ZeroWater |

ZR-0810N 10-Cup RedyPour Round Pitcher |

20 |

Pitcher |

|

ZeroWater |

ZBD-040 2.5 Gal Glass Dispenser |

20 |

Pitcher |

|

ZeroWater |

ZD-010RP |

20 |

Pitcher |

|

ZeroWater |

ZD-012RP |

20 |

Pitcher |

|

ZeroWater |

ZD-018 |

20 |

Pitcher |

|

ZeroWater |

ZD-022-RR |

20 |

Pitcher |

|

ZeroWater |

ZD-023-1 |

20 |

Pitcher |

|

ZeroWater |

ZD-030RP 30 Cup Ready-Pour Dispenser |

20 |

Pitcher |

|

ZeroWater |

ZD-20RPN 20-Cup |

20 |

Pitcher |

|

ZeroWater |

ZP-006 |

20 |

Pitcher |

|

ZeroWater |

ZP-007RP |

20 |

Pitcher |

|

ZeroWater |

ZP-010 |

20 |

Pitcher |

|

ZeroWater |

ZP-012-RR |

20 |

Pitcher |

|

ZeroWater |

ZR-0810GN 8-Cup RedyPour Round Pitcher |

20 |

Pitcher |

|

ZeroWater |

ZR-0810N 10-Cup RedyPour Round Pitcher |

20 |

Pitcher |

Interestingly, LG and Samsung make the only refrigerator filters that are NSF certified to remove PFAS compounds. Read my article on refrigerator filters and PFAS for more information.

Factors to Consider with Carbon Filters

If you are considering a carbon filter for your home, there are some factors you should keep in mind before making a decision.

Installation cost

A carbon filter can be installed as a point-of-use (POU) unit or as a whole-house system. Whole-house systems are also known as point-of-entry (POE) systems. POU systems are less expensive to install, but they only treat water at the sink where they are installed.

Whole-house systems are more expensive to install, but they will treat all of the water in your home. Typical installation costs for POE carbon filtration are between $1,300 to $5,000. The biggest cost is the labor to install the filter. If you’re handy, you can install the system yourself.

An under-sink carbon filter can be installed for less than $100. However, a filter this small would not remove all of the radon from your water.

Maintenance

Carbon filters require maintenance to keep them operating properly. The primary maintenance is replacement of spent carbon – spent carbon is media that has no remaining adsorption capacity.

Small, under-sink filters need to be replaced every few months. Large whole-house filters can last for 6 months to as long as 2 years before they need to be replaced.

Often, the carbon will become fouled with sediment or biological growth which would require replacing it more frequently. For a whole-house carbon unit, you have to remove the carbon from the filter vessel. This is difficult to do and, most people hire a specialty company to do this.

How often do I need to change the carbon

You need to replace the carbon when it becomes spent. This is the point where the media can no longer remove the contaminant from your water. For a typical residential system, a carbon filter has a service life of 6 months to 1 year. If your carbon becomes fouled with solids or biological growth, you may have to replace it sooner than this.

How much do replacement filters cost

POU carbon filters have a carbon cartridge that is replaced when the media is spent. The cost of an under-sink carbon cartridge is $30 to $350, depending on the size of the unit.

Whole house carbon filters require removing the spent carbon and adding fresh media to the vessel. The cost for this service is $1.40 top $4.50 per pound. A typical whole-house carbon system contains between 100 and 400 pounds of carbon – the cost for this service varies from $140 to more than $2,000.

Whole-house versus under-sink

You have two options when it comes to carbon filtration – whole-house and under-sink. Whole-house systems treat all of the water entering your home. They are more expensive to install, but they provide clean, safe water to every faucet and shower in your house.

Under-sink systems are less expensive to install, but they only treat the water at the sink where they are installed.

NSF certification

If you are planning to install a carbon filter for your home, you should look for NSF certification. The NSF certification mark means that the water filter has been tested for safety and to verify the manufacturer’s claims. Here are the NSF certifications that apply to caron filters:

- NSF/ANSI 42: Certified to reduce aesthetic impurities such as chlorine and taste/odor.

- NSF/ANSI 53: Certified to reduce a contaminant with a health effect. Health effects are set in this standard as regulated by the U.S. Environmental Protection Agency (EPA) and Health Canada.

- NSF/ANSI 401: Certified for emerging contaminants.

Other Treatment Methods that Remove PFAS

The EPA has been studying a variety of technologies to determine which are best for removing PFAS from drinking water. Their current recommendations include the following:

- activated carbon treatment

- reverse osmosis

- ion exchange resin

Reverse osmosis to remove PFAS and GenX

Reverse osmosis (RO) filtration is very effective at removing PFAS and GenX chemicals from drinking water. RO is typically more than 90% effective at removing a wide range of PFAS, including shorter chain fluorinated compounds.

Reverse osmosis uses a semi-permeable membrane to remove contaminants from water. The membrane allows water molecules to pass through, but it traps contaminants.

Reverse osmosis systems typically have a carbon pre-filter to remove any chlorine from the water before it enters the RO membrane. This is important because chlorine can damage the RO membrane.

RO systems can be used in both whole-house and under-sink applications. This technology is best suited for point-of-use treatment because of the cost and the amount of water that is wasted.

About 80 percent of the feedwater ends up as treated water, while the other 20 percent is kept as a concentrated waste. This concentrated waste, known as brine, can be difficult to treat or dispose, especially for a contaminant such as PFAS.

Ion exchange resin to remove PFAS and GenX

Ion exchange is a water treatment process that uses special resins to remove ions from water. This process is very effective at removing PFAS from drinking water.

Recent studies have demonstrated that ion exchange can remove virtually 100% of the PFAS from drinking water. There are two types of ion exchange resins: cationic and anionic.

Cationic exchange resins (CER) with negative charges can effectively remove contaminants that carry positive charges. Positively charged anion exchange resins (AER) are used to remove negatively charged contaminants, such as PFAS.

Ion exchange resins are like tiny powerful magnets that attract and hold the contaminants that pass through the media. Negatively charged PFAS ions will stick to a positively-charged anion resin. The resin eventually becomes spent and has to be regenerated or replaced.

The service life of PFAS resin depends on the specific compound, non-target compounds that might be in the water, the resin, bed depth, and flow rate.

Testing Your Drinking Water for PFAS

Simple Lab’s kit is a convenient way to find out if your drinking water is contaminated with PFAS. Their easy-to use instructions make it simple – wash your hands, put on the gloves they provide, fill the jar with tap water, and ship the sample to them in the same box they sent the supplies in.

Normally, you should receive your results within 1 week or 2 weeks. The report lists every compound they tested for and the results. Simple Lab also explains what the results mean, including whether you need to be concerned for your family’s health.

Read my review of the Tap Score PFAS test kit.

FAQs

Does reverse osmosis remove PFAS?

Reverse osmosis is very effective at removing PFAS and GenX chemicals from drinking water. Read my article on treating PFAS-contaminated water with reverse osmosis.

Does boiling water remove PFAS?

Boiling water does not remove PFAS or GenX chemicals from drinking water. In fact, boiling will actually increase the concentration of these contaminants, making it more toxic.

Does a water softener remove PFAS?

Water softeners do not remove PFAS. Although softeners use ion exchange resin, it is the wrong type for treating PFAS or GenX compounds.

Do refrigerator filters remove PFAS?

Refrigerator filters can remove a small amount of PFAS from water. However, they do not remove all of these contaminants and are not suitable for treating your drinking water.

Do Brita filters remove PFAS?

Brita filters can remove some small amount of PFAS from drinking water. However, they are not designed to purify water and should not be used to treat the water you drink.

Final Take

Activated carbon is an effective treatment method for removing PFAS and GenX compounds from drinking water. However, PFAS includes more than 4,000 chemicals, and some of them do not adsorb onto carbon. It is important to choose the right type of carbon filter and to make sure it is properly maintained. Carbon filters are not the only option for treating PFAS-contaminated water. Reverse osmosis systems and ion exchange resins are both effective at removing these contaminants from water.